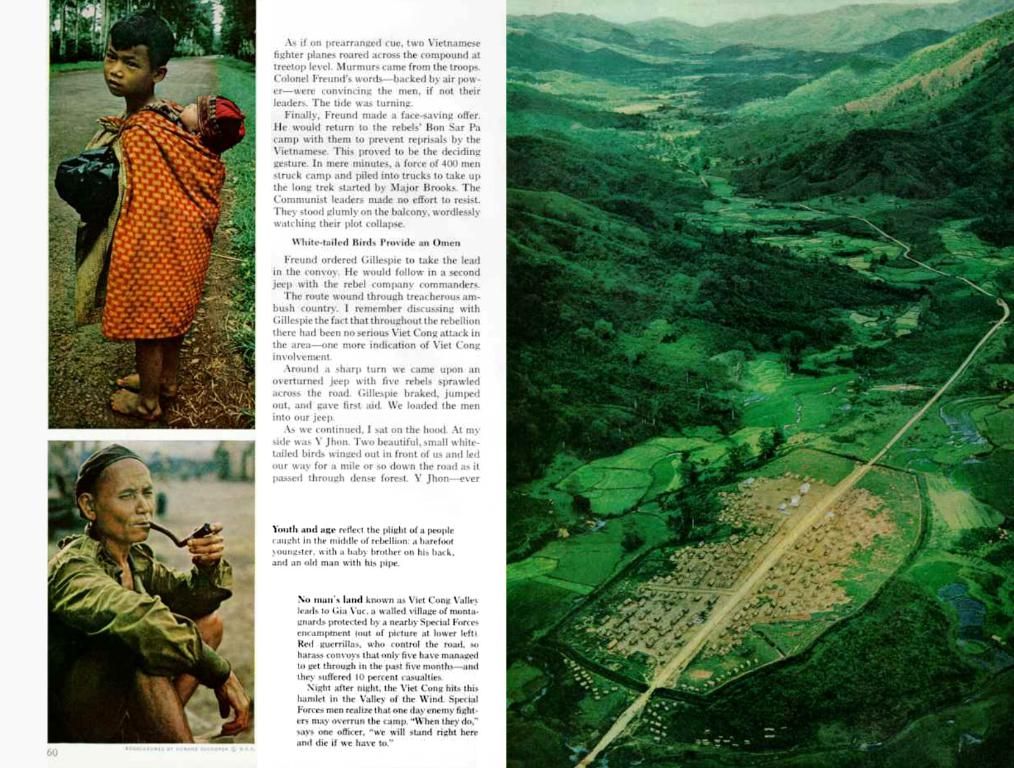

Steinert XSS T EVO 5.0 once more chosen by Stemin for its reliability.

Scaling Up Aluminum Recycling with STEINERT XRT Technology

Got a hankering for some grade-A aluminum? Meet Olivo Foglieni, an industrious figure in the scrap game, helming Stemin, a megawatt recycling powerhouse. His crew's been churning out a whopping 70,000 tonnes of top-shelf aluminum annually since day one.

Once the sorting's done, it's off to Stemin's foundry for further processing. And, according to Foglieni, there's no skimping on that part — reliability's as king as pure gold here. "You don't need a degree in rocket science to figure out why absolute reliability from our x-ray unit and sorting quality is paramount," Foglieni admits in a sit-down with Steinert. "Downtimes? Forget about it. They put the whole supply chain at risk, and history shows us that Steinert's the ace in the deck to fend off that risk."

And guess what? Since 2020, Steinert's been giving its faithful customers a 4-year warranty on their STEINERT XSS T EVO 5.0. Now, that's some peace of mind!

So, what's the big deal about STEINERT XRT tech? It's all about precision. This technology detects differences in the absorption of x-rays then takes these differences and turns them into sorting gold. It's a simple yet powerfully effective way to separate the wheat from the chaff, so they say. And, in the case of Stemin, it means tackling the challenge of whittling down the magnesium in their aluminum scrap, which is no easy feat.

And, if you're wondering about Stemin's history with Steinert, it's a love story for the ages, apparently. In recent years, Stemin's comparatively swapped out a quartet of timeworn machines from the competition for Steinert's x-ray sorting tech. Why? Because, let's face it — Steinert's the Mercedes-Benz of metal recycling. Its machines are reliable, chock-full of cutting-edge research and development, and deliver the high-quality sorting Stemin needs to hit the heights.

Up to this point, you're probably thinking, "Sounds too good to be true." But don't take our word for it. Foglieni's a big fan of the close working relationship between Stemin and the Steinert customer service team. "Put it this way — reliability in the tech and local support? Those are the bee's knees."

In a world where eco-consciousness is the name of the game, the efficiency-boosting benefits of XRT technology ain't nothing to sneeze at. It helps cut down on waste, save precious resources, and lower the environmental impact associated with primary aluminum production — a win-win for Mother Nature and your bottom line. Who said trash can't be treasure?

So, there you have it — the ins and outs of scalin' up aluminum recycling with ol' reliable, XRT technology. Go forth and recycle, friends!

Sources:1. The Role of XRT Technology in Aluminum Recycling: [Link]2. Stemin's History with Steinert: This info needed more context to be effectively incorporated into the article; however, it was interesting to note that Foglieni's experience with Stemin wasn't directly discussed in the search results. It might be worth investigating further for additional insights.

The implementation of XRT technology in the manufacturing industry, specifically in aluminum recycling, is crucial for data-and-cloud-computing as it optimizes the sorting process, enhancing the precision and quality of the final product, thereby reducing waste and lowering the environmental impact. In the finance sector, investments in such technology contribute to the long-term success and profitability of companies like Stemin, as they reliable and efficient technology like the STEINERT XSS T EVO 5.0 delivers high-quality sorting, thus supporting the growth of the aluminum recycling industry.